Check out Our Webinar Library

Welcome to our extensive webinar library! Here, you’ll find a diverse range of informative and insightful webinars on various topics, led by industry experts and professionals. Our webinars cover subjects such as technology, business, healthcare, education, and much more. Whether you’re looking to learn new skills, stay up-to-date on industry trends, or gain valuable insights, our webinar library has got you covered.

Don’t miss out on this valuable resource. Browse our webinar library today and start exploring our range of informative and engaging webinars!

How to Use 3rd-Party Materials on the Professional 3D Printer—XiP

Selecting the right materials for your 3D printer can make or break your 3D printer. While we’ve worked closely with the industry leaders on validated materials for XiP – the world’s first ultrafast desktop 3D printer -the beauty of an open platform printer is to allow users to experiment and validate their own resins. That’s why XiP is completely open for use with 3rd party resins. Upgrading from another platform but still have several containers of their resin and want to learn to use that on XiP?

CAD to Part with XiP in 30 Minutes or Less with Jasmine Heer

Sure, 3D printing overnight and coming in to find your completed print is fun but wouldn’t it be more fun if you could do that and multiple other projects all within one day? XiP is the first Ultrafast Desktop 3D Printer in the world. How? We’ve taken the already fast mSLA technology and made it even better with our proprietary LSPc industrial light engine. If that still sounds like hyperbole and marketing speak, well, you’ll just have to see it for yourself.

ABS, PP, PEEK 3D Printing... Resins?

Resin 3D printed parts – they’re pretty, but aren’t they delicate and brittle? They wouldn’t make for good production parts. If you think that, you’re not alone. For decades this was true, but over the last few years photo-cured resins have come a long way. Not only are they matching thermoplastics, but they’re outperforming them in many cases and, yes, they are being used in production. ABS, PP, and PEEK are just a few of the thermoplastics that now have resin analogs. How do these light-loving resins match up with their warm-weather counterparts? Let’s find out.

Is Desktop Manufacturing a Reality in 2023?

From overseas production to 3D printing in house with a desktop 3D printer this recorded webinar features two companies (Applied Rapid Technologies and Liquid Sound Technologies) who are already proving that local, on-demand manufacturing can be done today!

Learn Why MotoCilino Switched from Form to XiP

When Paul Cilino—owner of design engineering firm MotoCilino—researches a new 3D printer he doesn’t cut any corners. With over 25 years of experience as a mechanical engineer and machinist, Paul has come to rely heavily on his small fleet of desktop 3D printers. So why, in June of this year did he make the switch from Formlabs to XiP? How are things going for him? And maybe most importantly—is it time for you to consider doing the same?

Talking Tech with 3D Printing's CEOs (feat. Markforged and Quickparts)

Wondering what the future holds for 3D printing? The next tech breakthroughs? We sat down with three of the change makers in the industry to ask for their takes on tech, manufacturing, sustainability, and what that means for future users.

Redefining Productivity with XiP Pro

An in-depth overview of the new XiP Pro Industrial 3D Printer. We walk you through all the features and technical specifications of this powerful new printer that will take your additive manufacturing to a completely new level of productivity.

Zero-Waste, High-Throughput Manufacturing with QLS ♻

SLS continues to reign supreme as the preferred additive manufacturing technology for low-volume manufacturing of complex components. As more and more manufacturers turn to this technology to solve production needs and supply chain woes, important questions emerge—How sustainable is this process? How effective is this process for higher-volume manufacturing?

Launching the Ultrafast XiP Desktop 3D Printer

Watch as we lift the hood on our new ultrafast resin desktop 3D printer, XiP. Rapid prototyping with 3D printing has become more common in product design, and XiP brings new meaning to “rapid” at the desktop. We will cover how the mSLA process combined with Nexa3D’s proprietary LSPc technology achieves this, and ultimately delivers higher productivity.

Accelerating Development and Reducing Costs with xMOLD

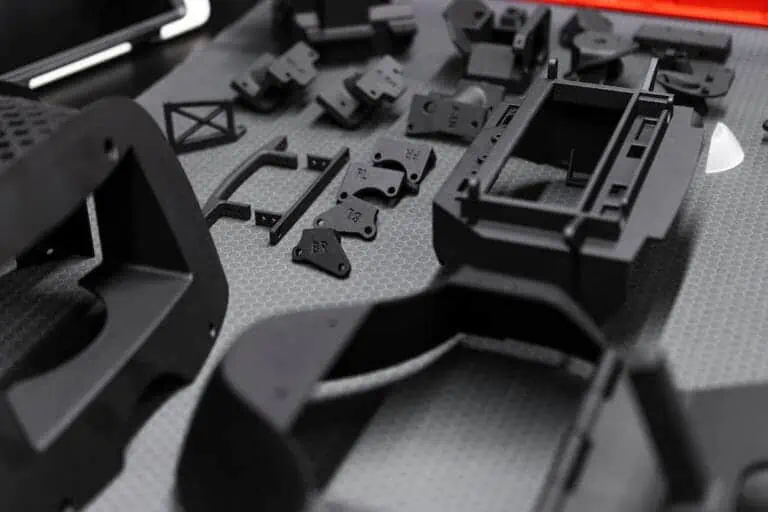

During this webinar we discussed Freeform Injection Molding (FIM) – a hybrid approach to digital tooling that combines 3D-printed freedom of design with the industrial strength of injection molding. The innovative approach to 3D printed tooling unlocks tremendous potential for contract manufacturers, regional molders, service providers and low-volume manufacturers looking to take full advantage of the design freedom, speed, and agility of 3D printing while using tried and true injection molding materials.

Produce Fast, Functional Prototypes with Freeform Injection Molding

In this webinar, our partners, Jeremy Smith and Clifford Green from Alpine Advanced Materials share how their full-service engineering and manufacturing firm uses Freeform Injection Molding (FIM) with high-performance materials to help aerospace and defense customers rapidly optimize design before high-volume production. Challenged with the inability to 3D print a filled material, Alpine implemented FIM in order to deliver fast, functional, and cost-effective prototypes to its customers.

What is LSPc®? Xometry Launches Nexa3D's End-Use Resin 3D Printing

In this recorded webinar, experts from Xometry and Nexa3D will unveil this new technology, its benefits, and how its engineered materials create functional, end-use parts useful across various industries, including commercial, medical, dental, and manufacturing.

How to Use 3rd-Party Materials on the Professional 3D Printer—XiP

Selecting the right materials for your 3D printer can make or break your 3D printer. While we’ve worked closely with the industry leaders on validated materials for XiP – the world’s first ultrafast desktop 3D printer -the beauty of an open platform printer is to allow users to experiment and validate their own resins. That’s why XiP is completely open for use with 3rd party resins. Upgrading from another platform but still have several containers of their resin and want to learn to use that on XiP?

CAD to Part with XiP in 30 Minutes or Less with Jasmine Heer

Sure, 3D printing overnight and coming in to find your completed print is fun but wouldn’t it be more fun if you could do that and multiple other projects all within one day? XiP is the first Ultrafast Desktop 3D Printer in the world. How? We’ve taken the already fast mSLA technology and made it even better with our proprietary LSPc industrial light engine. If that still sounds like hyperbole and marketing speak, well, you’ll just have to see it for yourself.

ABS, PP, PEEK 3D Printing... Resins?

Resin 3D printed parts – they’re pretty, but aren’t they delicate and brittle? They wouldn’t make for good production parts. If you think that, you’re not alone. For decades this was true, but over the last few years photo-cured resins have come a long way. Not only are they matching thermoplastics, but they’re outperforming them in many cases and, yes, they are being used in production. ABS, PP, and PEEK are just a few of the thermoplastics that now have resin analogs. How do these light-loving resins match up with their warm-weather counterparts? Let’s find out.

Is Desktop Manufacturing a Reality in 2023?

From overseas production to 3D printing in house with a desktop 3D printer this recorded webinar features two companies (Applied Rapid Technologies and Liquid Sound Technologies) who are already proving that local, on-demand manufacturing can be done today!

Learn Why MotoCilino Switched from Form to XiP

We sat down with Paul Cilino, owner of design engineering firm MotoCilino, to chat about his switch to XiP. He talks all about why he switched, what the transition has been like, and how XiP stacks up against the rest of his 3D printer fleet.

Talking Tech with 3D Printing's CEOs (feat. Markforged and Quickparts)

Wondering what the future holds for 3D printing? The next tech breakthroughs? We sat down with three of the change makers in the industry to ask for their takes on tech, manufacturing, sustainability, and what that means for future users.

Redefining Productivity with XiP Pro

An in-depth overview of the new XiP Pro Industrial 3D Printer. We walk you through all the features and technical specifications of this powerful new printer that will take your additive manufacturing to a completely new level of productivity.

Launching the Ultrafast XiP Desktop 3D Printer

Watch as we lift the hood on our new ultrafast resin desktop 3D printer, XiP. Rapid prototyping with 3D printing has become more common in product design, and XiP brings new meaning to “rapid” at the desktop. We will cover how the mSLA process combined with Nexa3D’s proprietary LSPc technology achieves this, and ultimately delivers higher productivity.

Accelerating Development and Reducing Costs with xMOLD

During this webinar we discussed Freeform Injection Molding (FIM) – a hybrid approach to digital tooling that combines 3D-printed freedom of design with the industrial strength of injection molding. The innovative approach to 3D printed tooling unlocks tremendous potential for contract manufacturers, regional molders, service providers and low-volume manufacturers looking to take full advantage of the design freedom, speed, and agility of 3D printing while using tried and true injection molding materials.

Produce Fast, Functional Prototypes with Freeform Injection Molding

In this webinar, our partners, Jeremy Smith and Clifford Green from Alpine Advanced Materials share how their full-service engineering and manufacturing firm uses Freeform Injection Molding (FIM) with high-performance materials to help aerospace and defense customers rapidly optimize design before high-volume production. Challenged with the inability to 3D print a filled material, Alpine implemented FIM in order to deliver fast, functional, and cost-effective prototypes to its customers.

What is LSPc®? Xometry Launches Nexa3D's End-Use Resin 3D Printing

In this recorded webinar, experts from Xometry and Nexa3D will unveil this new technology, its benefits, and how its engineered materials create functional, end-use parts useful across various industries, including commercial, medical, dental, and manufacturing.